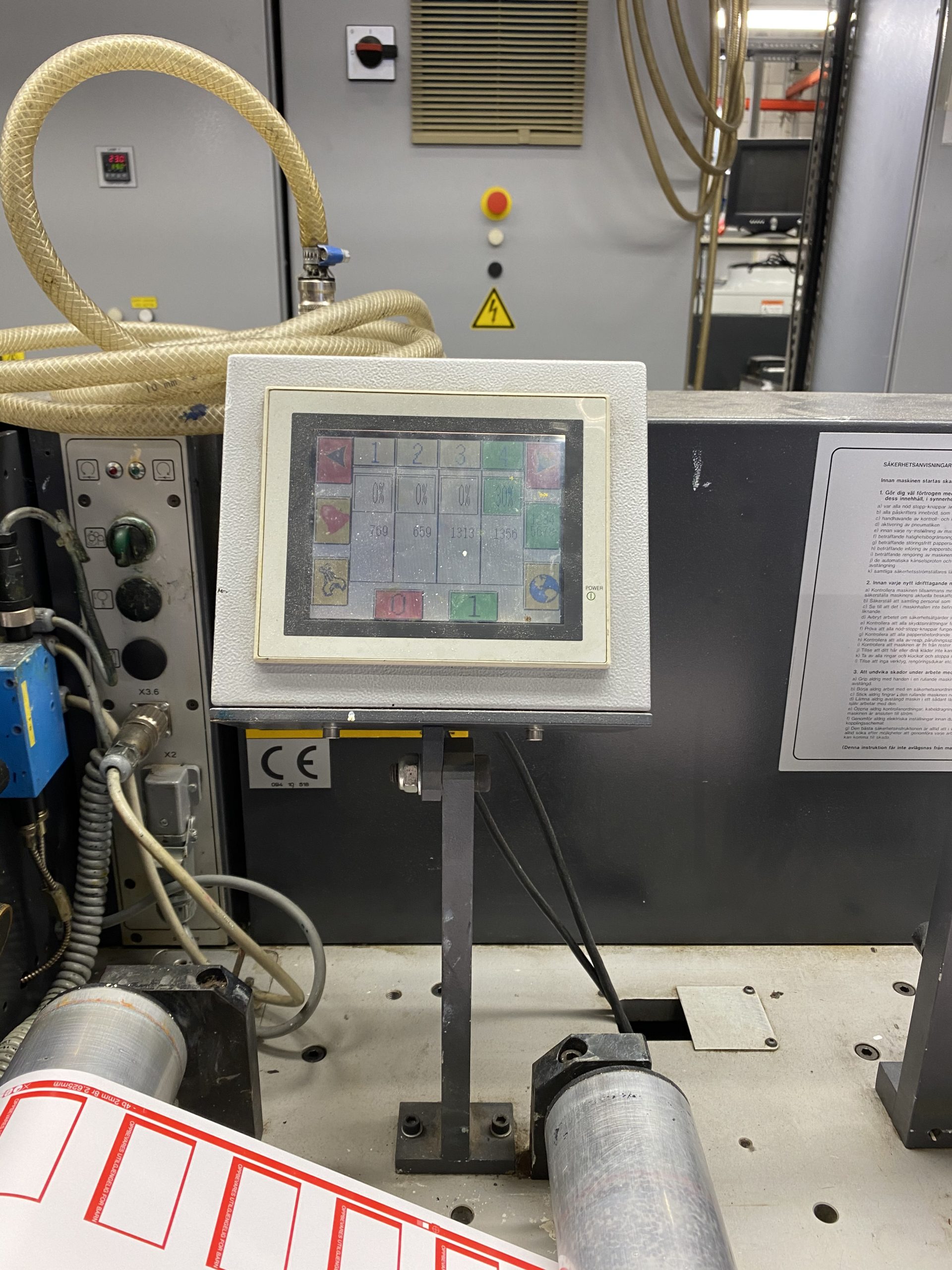

2005 Gallus EM 410 7 colours flexo label press

2005 Gallus EM 410 7 colours flexo label press

Excellent Flexo printing machine for immediate sale

Manufactured in 2005

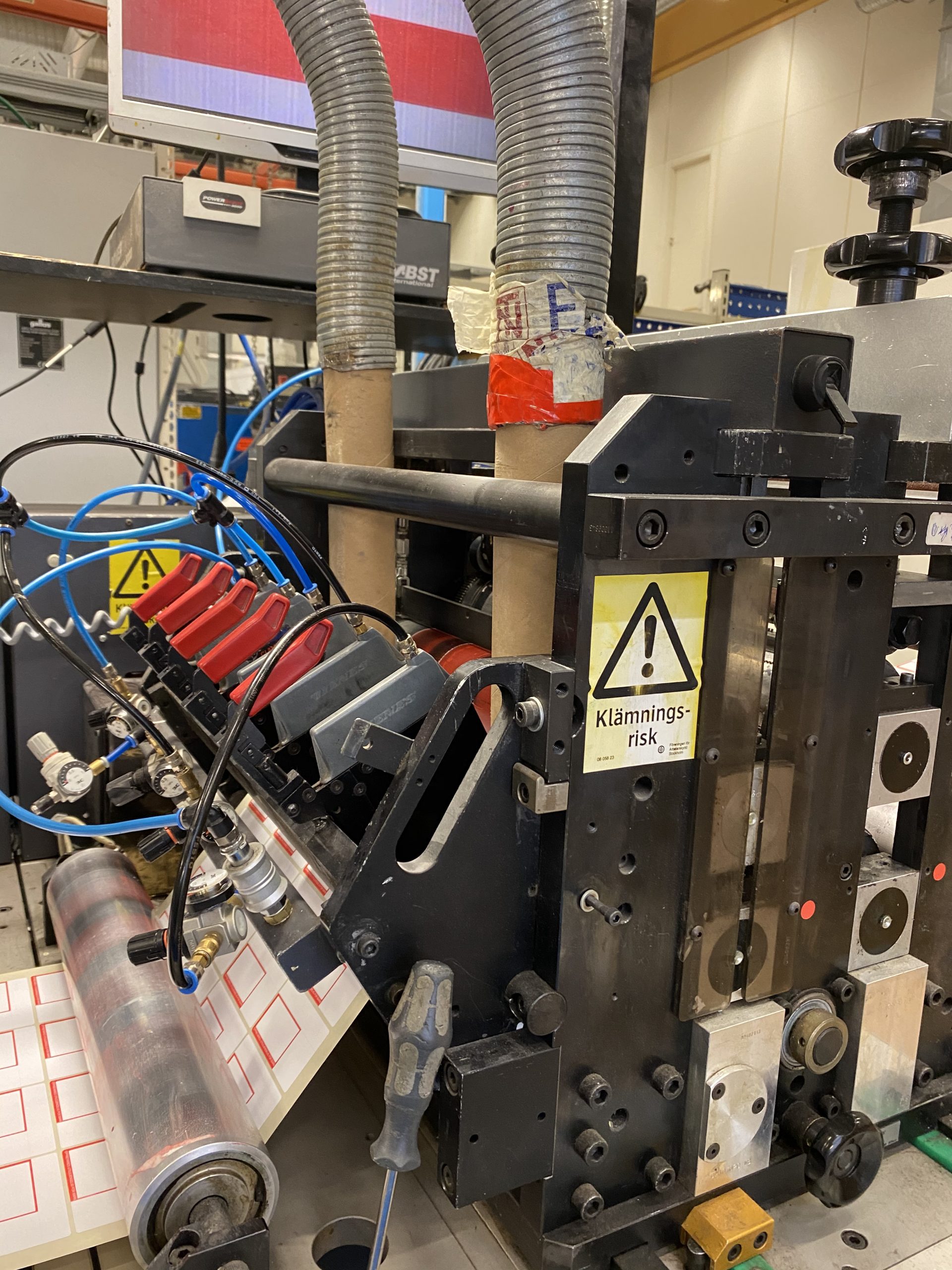

7 Flexo units, all with chilled rollers, and chiller

Double-sided corona treatment

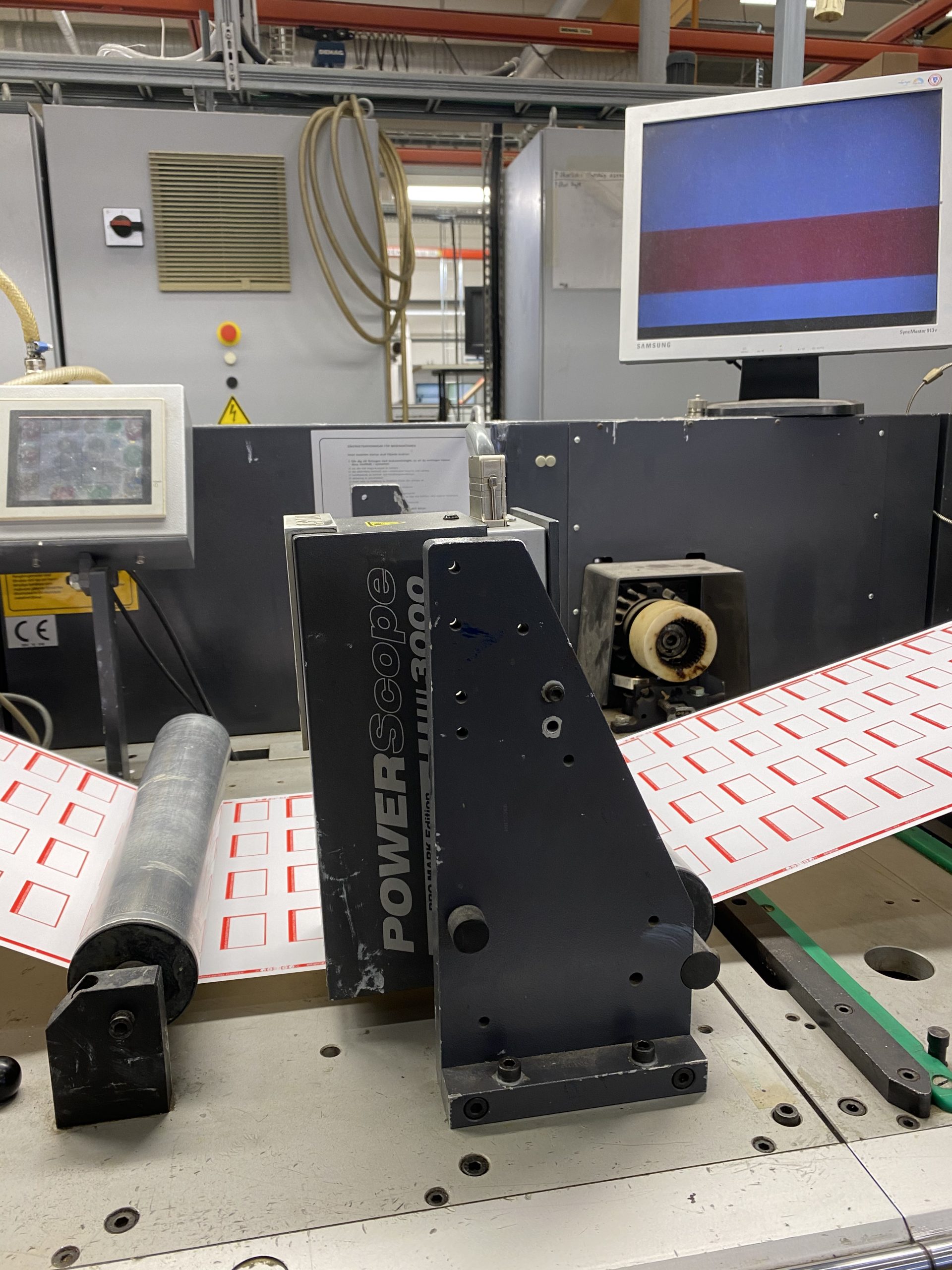

Rotary die-cutting station

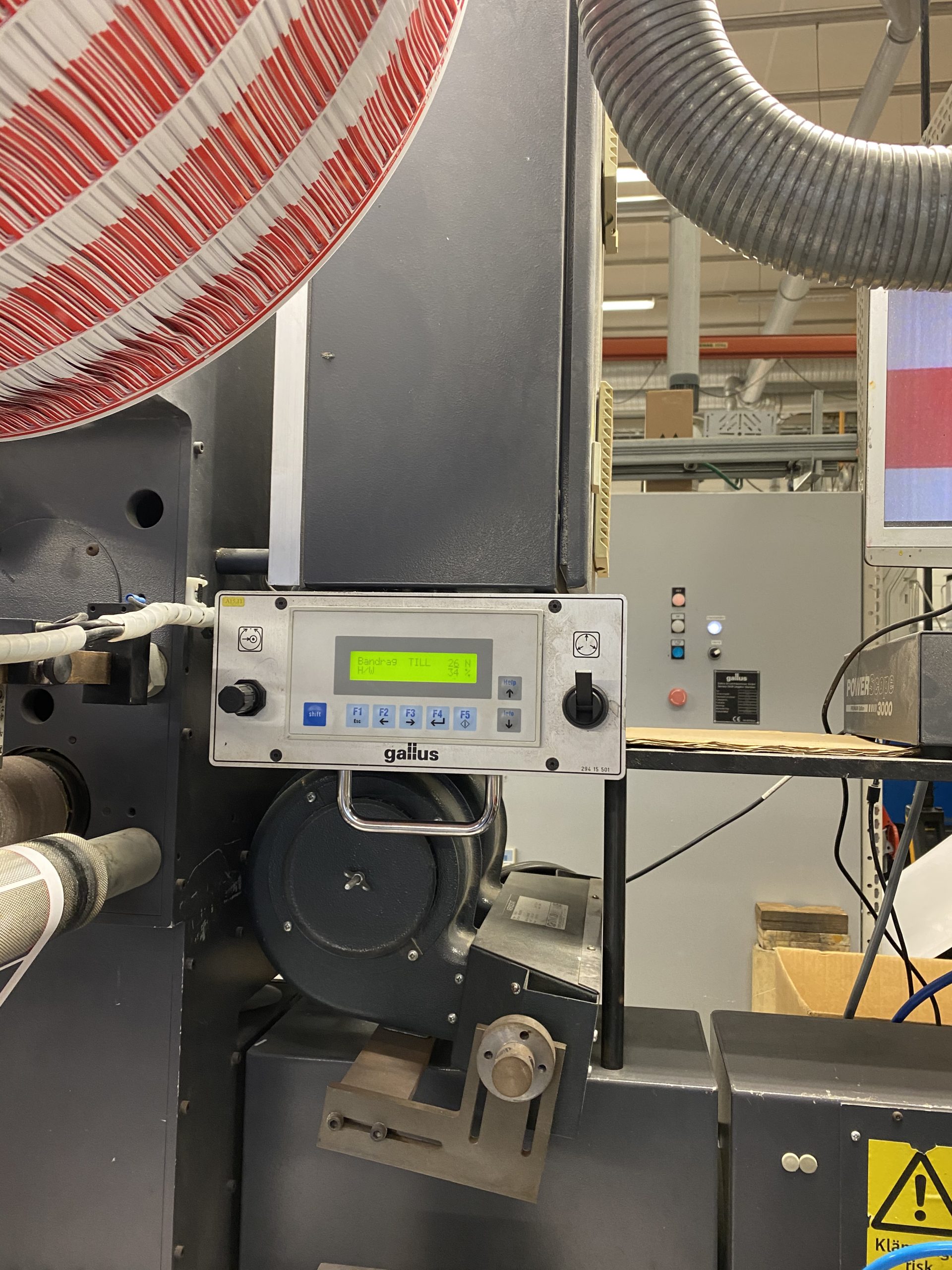

Matrix rewinder

Lot of aniloxes, and printing cylinders

Machine video on youtube: https://youtu.be/ZruGRw33pVU